Easy Floor Robotics

The I-Robot of the flooring market.

121% of funding target

Highlights

Highlights

The Robotic Revolution: Speed, Automation and Cost Reduction!

Our solution is efficiency and precision. EFR will bring the flooring market into the 21st century.

The world of construction is changing, and this is your once-in-a-lifetime opportunity to join the robotic revolution!

The EFR startup will make significant breakthroughs in the growing construction sector's flooring market. EFR will be the main player in one of the biggest markets in the world, the size of which is hundreds of billions of dollars with high yearly growth.

Not only is our innovative system highly efficient and accurate, but it takes care of the laborers' hard work, allowing you to say goodbye to those inefficient and time-consuming flooring methods.

Ditch those old, inefficient and time-consuming flooring methods and save contractors time and money. At Easy Floor Robotics, our innovative systems ensure contractors no longer have to face manual tasks such as loading materials, mixing, painting, sanding, and casting. Our revolutionary system enables contractors to quickly create incredible designs, bringing their business into the 21st century.

Autonomous robotic technology is the most efficient way to produce floor castings, ensuring you can always create perfect flooring.

This first-generation system provides a wide range of benefits, including:

- Saving tens of thousands of dollars a month on labor costs.

- Reducing manual labor and materials.

- Reducing applying time by 50%.

- Cutting 75% of the typical workforce needed

Technology is transforming every part of our lives, and it is no longer a question of whether robotics will enter the flooring world, but who will be the first.

Join the revolution today with Easy Floor Robotics!

Market potential – The growth potential is enormous. Experts forecast that there will be a high demand for seamless floors in the near future and the global market will grow by billions of dollars.

In recent years, the demand for big tiles and seamless floors has been constantly increasing.

In the commercial sector in particular there is a rising demand for unique and resistant floors.

- In the industrial markets, storage facilities, garages, gas stations, and underground parking lots, sealed coating is becoming an approved technical standard. From year to year, the demand for seamless flooring has been gaining momentum.

- Seamless floors have antibacterial coatings and do not have cracks where waste can get trapped.

- The flooring market has a huge growth potential! Summary report.

Unique Technology and Patents

- The Easy Floor Robotics application was reviewed by The U.S. Patent Office (WIPO) and they wrote that we are the first robotic technology in the flooring and floor coating fields. The U.S. Patent Office review can turn the company's value into hundreds of millions of dollars.

- The PCT application was written by the patent office and includes more than 60 pages. This PCT application could be a significant breakthrough in the flooring market with high protection from competitors.

- Part of the technology in the PCT application matches other markets, such as surfaces that are manufactured, kitchen surfaces, backsplash and countertops for the kitchen.

- Flooring is one of the oldest construction fields. Although in high demand, there has not been any significant breakthrough in this field technologically.

- The patent attorney reported to me that he was surprised by the search results and that: “very few industries offer such huge potential” and he did not find any robots in the flooring field.

Opportunity to invest in the I-Robot of the flooring market in the early stage.

E.F.R is developing the technology of the future.

Easy Floor Robotics has developed a unique concept for applying floors and was named one of the TOP 50 world-leading companies in the landscape of robotic solutions by the international magazine Built-Worlds, on the same list with ICON and Boston Dynamics (which was acquired by Hyundai ).

A senior representative from Icon (the largest company in the 3D construction field) told us that they know they will need to work with EFR or other subcontractors to finish floors on their construction sites, because none of the 3D printing startups have a flooring solution, and if EFR patents are strong, they may acquire EFR.

Market research forecasts that we will see the first fully automated construction site as early as 2025, which will eliminate the need for millions of construction laborers.

EFR robotics system is going to be the first robotics system that integrates several robots with a docking station, and it is going to be the first robotics system in the construction sector that has the ability to refill the materials autonomously.

The construction sector has five robotics startup companies, which have received millions of dollars in funding based on prototypes.

The companies: Skyline Robotics, Dusty Robotics, Toggle Industries, Scaled Robotics, and Okibo - are the companies that integrate robots in the construction sector.

For example, Okibo develops robots for wall rendering (e.g. stucco, exterior insulation and finish systems, concrete, primer, and adhesives) that can be used to simplify and reduce the costs of wall insulation.

There is no question that robotic technologies are going to transform the construction industry.

Our innovative system will help companies reduce manual labor, materials, and building costs, while saving them considerable time too.

The team is composed of a serial entrepreneur and three experts in the flooring, robotics, and polymer materials fields.

Mr. Lior Ferdman is the founder and CEO of Easy Floor Robotics.

Lior has more than 10 years of experience in the start-up field. He graduated from the Kiryat Ono Academy with a Bachelor's Degree in Business Management, specializing in Accountancy and Information Systems.

Lior is the founder of the MeetMeet App, (application for social meetings) and Smart Wheels 2Go (speed limit system for wheelchairs and strollers), which has won many competitions for entrepreneurs, including “Biztech 2011” at the Technion; this startup received funding and final patents.

Director of development:

Mr. Amnon Demri, the robotics expert, will serve as the director of development. He has years of experience in consulting and assisting startups, companies and corporations in the fields of civilian and military mobile robotics.

Amnon was the CTO of one of the biggest military robotics companies, and he has extensive experience in management of developing robotics projects.

Flooring advisor and consumer design:

Mr. Uri Rabinek will serve as the flooring advisor and consumer design manager. He is the CEO and founder of TechnoCrete and has more than 30 years' experience working with epoxy, self-leveling underlayment, and MicroTopping.

He is a certified Concrete Inspector (by The American Concrete Institute). He is also an exclusive representative of several international brands in Israel.

Chemical advisor:

Mr. Ged Lewitus will serve as the chemical advisor. He is a chemical expert, chemical and polymer engineer, and has over 12 years' experience working with various polymer materials.

The companies LATICRETE (USA) and IDEAL WORK (Italy) - two huge corporations in the field of flooring materials, will supply materials and knowledge for the project.

.jpg)

Easy Floor Robotics in the Media -

Pitch

Pitch

The problem

We can separate flooring problems into four areas: human, economic, design, and hygiene.

To better understand the problems in the flooring process, you are welcome to watch the video below.

We and our experts believe that this application process can be done with two laborers and one robotics system.

Human Aspect: As you can see in the attached video, the flooring process is tiring work - - the laborers are working on their hands and knees, and all of the tasks of applying flooring are done manually: mixing, loading the materials into the mixer bucket, casting, painting, sanding, shoveling, and even creating texture. As a result, it is difficult to create a consistent, high-level finish.

Most errors result from a lack of professional skills.

The construction industry wants to reduce the numbers of laborers on sites following a number of industrial accidents in the industry

Economic Aspect and Environmental Impact: in the US & Japan, the construction sector has a severe shortage of skilled labor.

Nearly 80 percent of construction companies have been unable to find the workers they need.

The number of workers in the construction industry is decreasing, young people do not want to work in the construction industry, the average age of construction workers in the US and Japan now being over 50 years old.

Another advantage of our system is zero waste production - which is the result of increased efficiency, productivity, and automation of the system.

The robot uses the exact amount of materials that the project needs, compared with traditional flooring methods that use 10 percent more than is needed and a large portion of materials becomes waste. 3D printing is a sustainable technology that can help reduce environmental impact.

In the US, rising labor costs have significantly increased the house construction prices. Construction costs have jumped 40 percent since 2004.

Design Aspect: The problem with customization - the architect is forced to choose tiles from standard designs that are available in the market.

In recent years, the demand for big tiles and seamless floors has been constantly increasing.

In particular, in the commercial sector, there is a rising demand for unique and decorative floors.

Our technology gives every client the ability to design their own floor - from the drawing board to reality.

Hygiene Aspect: Standard tiles have cracks where waste and bacteria can get trapped. In order to tackle this issue, industrial floors use sealed flooring and this technical standard is going to be a new standard in commercial kitchens, hospitals, medical clinics, public toilets and showers.

Seamless floors have an antibacterial coating and don’t have cracks where waste can get trapped.

The Solution

The innovative Easy Floor Robotics systems have been designed to provide solutions in four key areas, Resistance, Speed, Innovation, and Reduction.

Our solution is the development of technology similar to the famous I-Robot for the flooring market that integrates several robots for applying floors and a docking station with materials that are available on the market, such as epoxy and Micro-Topping.

EFR’s system creates precision flooring in half the time compared with traditional flooring methods and cuts 75% of the usual necessary workforce, with a high-level finish that no human hand can achieve.

Our robotics system is able to work with all types of polymers: liquid like epoxy, powder like Micro Topping, or decorative concrete, and it is even able to apply green products like linoleum made of cork.

The Technology

We are developing software and hardware using machine learning, AI, computer vision, and mapping algorithms technology.

Easy Floor Robotics has developed a unique concept to integrate robots into a simultaneous working environment, creating the most efficient floor coating possible.

Our revolutionary solution is the development of technology similar to the famous I-Robot for the flooring market, that integrates several robots for applying floors and a docking station, with autonomous recharging, offloading, and loading materials, as well as the ability to work with laborers, avoiding obstacles and mapping out space.

The development will be carried out under the guidance of Mr. Rabineck, The CEO of TechnoCrete and our consumer design manager. Mr. Rabineck has over 28 years' experience working with Epoxy, self-leveling underlayment, topping, and he also is an exclusive representative of several international brands in Israel.

EFR robotics system is going to be the first robotics system that integrates several robots with a docking station, and it will be the first robotics system in the construction sector that has the ability to refill the materials autonomously

In the first years of the robotics system, the robot will do the same tasks as the laborers, but autonomously - more efficiently and with greater precision.

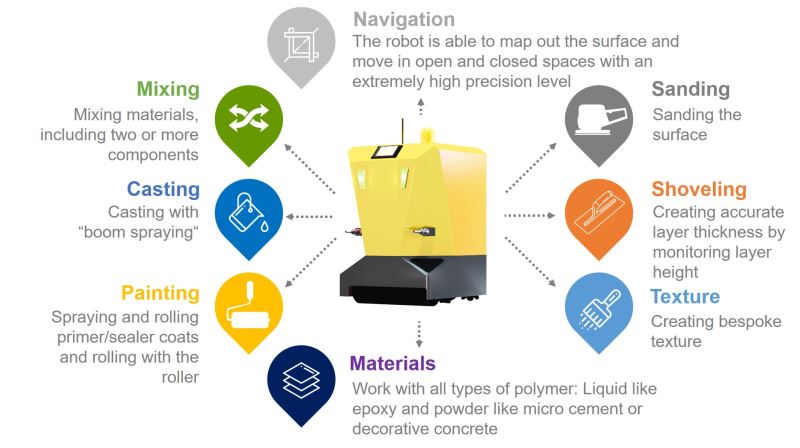

system abilities:

- The robot is able to map out and move in open and closed spaces with an extremely high precision level.

- Applying materials, including two or more components, with precision monitoring.

- Recharging ability, offloading, and loading of materials at the docking station.

- Creating accurate layer thickness by monitoring layer height

- Painting and applying primer and finish coat and sealer.

- Creating bespoke texture.

- Automated self-cleaning when the robot finishes the application/casting process.

Team

Team

|

Mr. Amnon Demri, the robotics expert, will serve as the director of development. He has years of experience in consulting and assisting startups, companies and corporations in the fields of civilian and military mobile robotics.

Amnon was the CTO of one of the biggest military robotics companies, and he has extensive experience in management of developing robotics projects.

|

|

Mr. Uri Rabinek will serve as the flooring advisor and consumer design manager. He is the CEO and founder of TechnoCrete and has more than 30 years‘ experience working with epoxy, self-leveling underlayment, and MicroTopping.

He is a certified Concrete Inspector (by The American Concrete Institute) and he is also an exclusive representative of several international brands in Israel.

|

|

Mr. Gad Lewitus will serve as the chemical advisor. He is a chemical expert, chemical and polymer Engineer, and has more than ten years‘ experience working with numerous materials.

|

|

Gavriel graduated from The Cooper Union with a degree in Electrical Engineering and Computer Science. He has over 10 years of experience in robotics startups including roles as CTO and head of engineering. He has led multi-disciplinary development teams in the R&D of a social robotics platform and multiple generations of humanoid robot prototypes. He is a serial inventor, holds a U.S. patent and has several patents pending in the fields of social and mobile robotics.

|