Olive X-Press

Olive X-Press has developed the world‘s first olive oil production machine for the home! Consumers will be

154% of funding target

Highlights

Highlights

Disrupting a Huge But Outdated Market

The olive oil industry is massive, but at the same time it is also outdated, anachronistic and suffers from many problems. The olive harvest is short and occurs once a year. Once harvested, olive acidity rapidly increases and requires immediate fresh olives milling. Industrial production combined with the lack of fresh olives (all other olives are pickles…) lead to a product "shelf life" of many months, during which time the quality, taste, smell and aroma of olive oil deteriorates. In addition, the market is saturated with various scams, including hot-pressing being passed off as cold-pressing, use of cheap blended oils, and even the sale of expired oils! Global demand for olive oil has risen by an average of 73% over the last 25 years, with particularly impressive leaps in the world's largest countries.

Today, truly fresh olive oil can be enjoyed for only two months during the olive harvest period, while the olive oils sold to the public are usually several months or even more than a year old. After about two months, the chemical quality of olive oil start to deteriorate. The taste, smell and aroma are damaged, as are its health benefits. Olive X-Press is revolutionizing the field with a technology enabling the production of fresh, high-quality olive oil throughout the year, anytime, anywhere!

A Patent Holding, Future Market Leader

The technologies developed by Olive X-Press allow for the creation of cold-pressed high quality olive oil, using three exclusive registered patents for this purpose: A patent for a small olive press mechanism, a patented technology for separating oil from water, and a bio-tech patent for preserving oil cells within olives for a long time. The technologies developed by the company have a variety of exclusive advantages, mainly: Home production and user experience, an innovative response to the growing global demand for fresh olive oil (smell, taste, aroma) in a way that completely changes the existing market. Olive X-Press's technology is mostly scalable from home-use to commercial use (supermarkets, delicatessens, restaurants) and has already begun to interest various food giants. The patent covers both the machine and the shelf-life extension of the olives, thus placing the company at a significant commercial advantage.

Market Ready with Promising Business Model

The company has so far developed four functioning prototypes of the home version, which have been showcased in exhibitions and events around the world. In the first stage, the company is expected to nurture a new and primary market for the production of homemade olive oil, in which it will sell oil machines for domestic use, along with a service for the supply of fresh treated olives in packages, smiliar to the familiar coffee capsules concept. In the second stage, based on proven technology of supplying fresh olives to the market, the company is expected to produce and market a larger olive oil machine - a commercial model intended for use in supermarkets, delicatessens and restaurants - and will work to expand its influence on the global olive oil industry.

Pioneering a Potential Market Leader

In 2014, 3.8 billion liters of olive oil were produced worldwide, of which about 3.5 billion liters were consumed during that year. With tens of millions of people living in the Mediterranean region, an area rich in olive trees, and hundreds of millions around the world who do not live near olive trees and are dependent on commercial olive oil that has been bottled for many months, Olive X-Press brings a real advantage to the consumer and commercial markets.

Developed by World-Renowned Experts & Backed by US Investors

The development of Olive X-Press has so far been carried out through an initial investment by a group of American investors under the supervision of Prof. Zohar Kerem of the Faculty of Agriculture in Rehovot, a world renowned expert in the field of olive oil. The company's technological developments for the machines and the technology of extending the shelf life and freshness of the olives were created in cooperation with leading professional bodies including the Hebrew University of Jerusalem and the Institute of Biochemistry, Food Science and Nutrition.

Pitch

Pitch

The Problem

In contrast to the world's leading trends in food consumption, including the trends of fresh, healthy and organic food, plus the move towards preparing home-made food using the Do It Yourself method, olive oil, a product of extraordinary qualities, is still being produced in an obsolete and archaic manner that poses many problems.

Among other things, due to the sharp rise in acidity that immediately occurs after a fresh olive harvest, it is necessary to press the olives no later than a few hours after the harvest. The oil is expressed using existing conventional large industrial pressing machines, and then is distributed throughout the year in bottles and cans - until the next harvest season. During this long period, the chemical quality of olive oil deteriorates and its taste and smell are damaged - in the same way that coffee loses its intensity after it is ground. Most of the olive oil sold in the US, for example, is between six months - two years old (!), during which time nutritional and health values deteriorate.

Another well known problem is the fact that the global oil market tends to be saturated, literally, with various kinds of scams, which means that oil does not meet the actual definition of quality olive oil, even though it is marketed and priced as such. Among other things, many manufacturers perform hot-pressing instead of cold, use cheap mixed oils, and even sell expired oils. In the absence of an accessible domestic solution for the production of fresh olive oil, consumers are forced to rely on these products and often receive low quality merchandise, sometimes with the possibility of actual harm to their health.

The Solution

Olive X-Press has developed a dual and integrated technology:

• The first home olive oil machine in the world, with an initial prototype that is part of a planned series of machines of different sizes, for different uses.

• Natural technology with the possibility of commercialization in an inexpensive way, to extend shelf life for fresh olives, in a way that allows the production of fresh olive oil throughout the year, anywhere in the world.

A similar solution has been applied in the field of coffee. The coffee bags that were once sold in supermarkets, with flavorless and odorless pollen content, with no production and expiration dates, were replaced by small household machines and capsules that retain chemical qualities, taste, and smell.

Development was carried out with an initial investment by a group of American investors, under the supervision of Prof. Zohar Kerem of the Faculty of Agriculture in Rehovot, a world renowned expert in the field of olive oil.

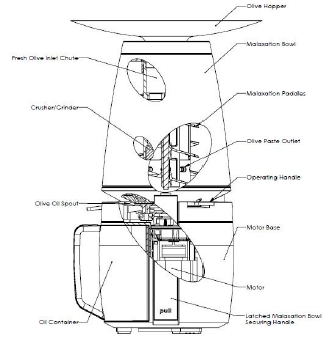

How does it work?

With a single press, in a silent operation and in just 45 minutes, the Olive X-Press is able to cold press 3 kg of olives (capsule-treated olives or freshly picked olives) using three exclusive registered patents for this purpose, based on natural treatment technology for olives, which allows the production of fresh olive oil throughout the year!

Fresh olives, or capsules, are fed into an initial crushing mechanism. The crushing of the whole olives leads to the formation of porridge. This crushing mechanism is efficient and innovative, because it is quiet in action, tiny and allows for implementation inside a home machine, and does not increase the temperature of the olives when breaking the pits (a phenomenon that exists in industrial mixers and harms the quality of the oil). In the second stage, a malaxation of all the porous material is performed, during which oil is extracted from the oil cells in the olive. The third and last stage uses exclusive patented technology that separates the oil from other porridge materials and fluids. Unlike most of the existing mechanisms in the presses - centrifuges - we used the household machine to separate oil based on filter and form of the entire mechanism. The fresh oil has a transparent receptacle ready for use.

Treatment of fresh olives for the preservation of their freshness - a natural process, at the end of which the olives are preserved in vacuum packaging. The equipment needed to implement the process is present in the market, including olive Selection (this is done in edible olives, in olive oil this step is abandoned, with the understanding that the customer does not see what goes into the oil produced...), vacuum packaging equipment, and storage refrigerators. The total cost of implementing the process is similar to the use of pickled olives in packages of similar sizes. The development of this unique process has earned the company a patent.

Advantages of fresh olive oil:

• Contains essential fatty acids - necessary for maintaining good health

• Contains anti-oxidants - olive oil is rich in polyphenols containing powerful antioxidant and anti-inflammatory properties

• Contains vitamin K - has a critical role in the process of blood coagulation and formation of blood clots

• Contains calcium - for strengthening bones and preventing diseases of bone degeneration such as osteoporosis

Advantages of our technology:

• Innovative technology that enables the minimization of large industrial pressing machines to a compact and domestic product.

• Future product versatility - development potential for a large commercial market: supermarkets, delicatessens and restaurants.

• The first solution to the problem of freshness and quality of olive oil throughout the year, as well as the problem of fraud and lack of consumer confidence. The absolute control of the process - from the purchase of olives according to choice and the taste of the customer, for a cold pressing process performed right in front of their eyes, and ending with fresh olive oil, preserved chemical values taste, smell and aroma, includes a user experience of the whole process.

• The technology contains a great deal of knowledge both from a research body and from internationally renowned experts who have shaped it and brought it to commercial maturity. The proof of basic development will allow continued development of machines of various sizes and uses (OUTDOOR, a machine for small farmers, etc.), as well as extension of shelf life for many other olive types.

Development

The company has so far produced four working and functioning prototypes, which have been shown in demonstrations and events around the world. With the funds raised, the stage of design and planning of the serial machine will be completed into a working product ready for mass production, which will produce about 500 CC single batch of oil out of 3 KG fresh or treated olives, while maintaining maximum freshness, taste and quality of the oil.

In addition to the machine, the company has developed a revolutionary technology that enables the shelf life of the fresh olives to be increased by a natural and unique method, enabling consumers to produce and consume fresh olive oil in cold pressing at any place and at any time, as needed. Commercially, this technology has a broad effect. As in the coffee world, machine buyers will buy fresh olive capsules whenever they wish to use them to create and consume fresh oil.

The company plans to develop and market a commercial model for supermarkets, delicatessens and markets, and will consider setting up a global arm in the US or another major location in the world.

Registered patents

• Machine olive crusher - US patent 8677894. Crushes the whole olives and brings them to a porridge form for the melting stage. Efficient and innovative because it is quiet in action, tiny and allows for implementation inside a home machine, and does not increase the temperature of the olives when breaking the pits (a phenomenon that exists in industrial mixers and affects the quality of the oil)

• Machine oil separation - US patent 8,877,273 - This technology deals with the separation of oil at the end of the extraction process, after the crushing of the olives and the implementation of the malaxation phase. Unlike most of the existing mechanisms in the presses - centrifuges - this new tech works in the form of a separation based on the filter and form of the entire mechanism.

• US patent 8,381,206 - Natural technology with cheap commercial application, enabling the handling and packaging of fresh olives in a way that can produce fresh oil over a year - until the next harvest.

Continue planned milestones for development

1. Within 6-8 months, a serial design will be completed for an existing prototype, enabling entry into the manufacturing process of the home machine by granting a license to the manufacturers.

2. Within 4-6 months, computerized design of a larger machine designed for restaurants, delicatessens and supermarkets.

3. Establishment of a number of production and shipping points for treated olives for the market (initial expected - California and South-West Europe).

4. In another 8 months - commercial production of the home machine (2019).

5. In another 6-8 months - developing a larger scale prototype for supermarkets.

The first two milestones are planned to occur using current funding. Their completion will enable achieving a significant milestone in terms of commercialization relevance and increasing the value of the company.

Team

Team

|

Professor of Food Chemistry, Institute of Biochemistry, Food and Nutrition, The Hebrew University of Jerusalem.

One of the world‘s leading experts in the chemistry of olives.

A member of the national committee for nutrition security, the deputy chair of the higher committee for food standards, head of the expert committees for trade standards of olive oil and of edible oils at the ‘Standards Institution of Israel‘, Israel‘s delegate to the Chemists‘ Expert Group of the International Olive Council and a member of USP Pharmacopoeia experts panel on olive oil authentication.

|

|

Former fighter pilot. Held various managing positions on the defense and high-tech industries.

|

|

He has a mechanical engineering degree from the Technion, has been providing development services in the field of mechanical engineering for more than 20 years, and has been involved in the development of many products.

|